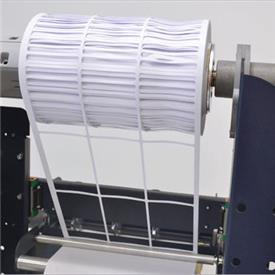

Matrix remover and slitter

Easy to operate, less headache!

Full bleed labels? Not a problem! Our matrix removers were born to assist you!!

Our matrix removers were specifically designed to reduce the stress when printing full bleed labels.

Thanks to our units, you can load die cut label rolls, slit the rolls (if you need this option) and remove the matrix and this can all be done with a variety different of printers.

The matrix removers give the user the ability to remove the waste material from printed or blank pre die-cut rolls of labels up to 240mm (9.45”) wide onto 3” cardboard core and having an outside diameter up to 250mm (10”). The finished labels will be rewinded face out only.

Perfect full bleed labels can be achieved on pre die cut media after the waste material is removed.

The production of edge-to-edge printed labels on roll will become extremely easy and quick.

Two different models are available. The smallest MCH100MTX17 (without slitter module) or the large version named MCH100MTX25.

Workflow optimization

The main benefit in choosing the offline matrix remover is that it can complete each job without any interruptions that can be caused by the laser printing engine. Since the media will be loaded into the matrix remover at the beginning of the job, this reduces production time making this unit very time efficient. Being that it’s an offline solution, the matrix removing and slitting operations will not be interrupted if the printer decided to pause or cut the media during the standard printing process.

The pressing roller shown below positioned above the waste core holder facilitates the matrix removal from the die-cut roll, reducing the risk of tearing and ensuring more precise operation of the machine.

Key Features

- Order pre die cut rolls of labels with waste

- Print on pre die cut rolls (with 2 mm per side)