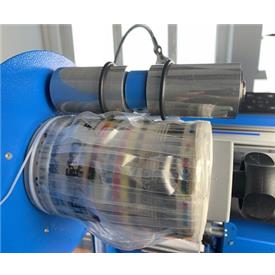

DTM LF140e Label Finishing System

Digital On-Demand Short Run Label Finishing Solution

The LF140e is a compact system for simple, fast and cost-efficient label processing on-site. It can be used to handle all the operations involved including unwinding the pre-printed rolls, laminating and digital contour cutting, waste matrix removing, slitting and rewinding the finished rolls. Pre-printed rolls with a media width between 100 mm (3.94″) and 140 mm (5.51″) and a maximum roll diameter of 200 mm (7.87″) can be processed making it the ideal addition for all types of roll printers, such as the inkjet printer LX2000e from Primera Technology, Inc. or the toner-based LED printer OKI Pro1050.

Noteworthy is the optical black mark registration through an integrated camera and LED spotlight, which guarantees an accurate repetitive precision even with complex cuts.

In addition, the control unit of the DTM LF140e really stands out. With the integrated 11.6″ touch screen all functions and processes can be controlled. Also included are numerous connections such as USB, Ethernet and also WLAN connectivity for accessing external cutting jobs.

Features:

Borderless output: the production of labels with full bleed has been a nightmare up until now, as many roll printers do not support it. Now it is no longer necessary to pay attention to a precise label edge when printing in full bleed, nor is it necessary to set up a minimum distance between labels.

Time and cost savings: producing short runs of labels in-house means reducing storage space and costs. There is also no need to order pre-cut label rolls.

Resistance of the labels: lamination increases the durability of the labels. Any paper material, whether inkjet or dry toner based, can be coated, eliminating the need for special durable label materials.

Specifications LF140e Label Finishing System

| Input/Output max. roll diameter: |

200 mm (7.87″) |

| Media width: | 100 mm (3.93″) - 140 mm (5.51″) |

| Max. cutting width: | 122 mm (4.80″) |

| Label length: | 10 mm (0.39″) - 350 mm (13.77″) |

| Min. slitting width: | 19 mm (0.75″) |

| Max. number of slitting blades: | 6 |

| Roll core size: | 76 mm (3″) |

| Max. media thickness: | 0.23 mm (0.05 mil) |

| Max. cut speed: | 600 mm/s (24 in/s) in all directions |

| Controls: | Integrated 11.6″ touch screen PC |

| Power requirements: | 100 V - 240 V AC, 50/60 Hz |

| Energy consumption: | 29 W Idle, 60 W Active (100 W peak) |

| Certifications: | UL, UL-C, CE, FCC Class A |

| Dimensions (WxHxD): | LF140e: 116 cm x 68 cm x 78 cm/105 kg Worktable: 124 cm x 79 cm x 88 cm/49 kg Shipping palette: 137 cm x 93 cm x 101 cm Total weight: 210 kg |

| Warranty: | 36 months (after product registration), wearable parts 1 year |

Plotter Specifications

| Linear cut speed: | Dependent on shape complexity |

| Programmable cutting force: | 4.41 N (450 gf) in 38 steps |

| Cut precision: | ±0.3 mm (0.012″) |

| Drive method: | Digital servo drive |

| Test cut function: | Yes |

| Black mark registration: | Camera recognition via 2 mm² or 4 mm² blackmark |

| Display: | Graphic type LCD with backlight (240 dots x 128 dots) |

| Cut ability: | Printed and blank media |

| Data interface: | RS-232C/USB 2.0 (High Speed) |

| CPU: | 32-bit CPU |

| Interface & Software: | DTM Print LF140e Label Finishing Software |

| Certifications: | UL, UL-C, CE, FCC Class A |

| Manufacturer: | Graphtec |

Key Features

- Open frame construction - easy media loading with an open front side

- Ultrasonic media tension control - means no moveable sensor parts to fail

- Camera sensing - more accuracy and speed in cutting

- Blank label production - converting blank stock into die-shaped rolls for printing afterwards

- Matrix pressure roller - to avoid media jam on complex matrix shapes by flattening the uptake material

- Remote assistance - if connected to the internet we can offer online support and remote FW/SW upgrades

- Steel workbench - for precise levelled installation whilst still moveable on site

- Proudly made in Europe with a solid 3 years warranty (wearable parts 1 year)